Researchers at Oak Ridge National Laboratory (ORNL) are taking a closer look at metal halide perovskites, which when combined with 3D printing, can enable a new breed of high-performance solar batteries.

Metal halide perovskite materials have gained traction over the past decade due to their ability to convert solar light into electrical energy: a process known as photovoltaic conversion.

Unlike many before it, the new study leverages advanced equipment at ORNL’s Center for Nanophase Materials Sciences (CNMS) to investigate the structure of metal halide perovskites. Crucially, the research also dives into how this structure interacts with phenomena such as ions in motion to actually generate electrical energy from light.

The team believes its work could enable the design of more efficient and more robust solar-cell batteries and other photovoltaic devices, including 3D printed ones.

“These materials have mostly been studied under static conditions,” explains Yongtao Liu, lead author of the study. “We studied the materials in real-time so we could understand such variables as how the ions are moving. You can’t get a complete picture otherwise. Our findings suggest these ion migration patterns are key to efficiency in converting solar energy to power and the stability of the solar cells.”

Metal halide perovskites

Metal halide perovskites are a class of crystalline metals known for their ability to harness light energy and generate electrical energy. With the demand for renewable energy rising as fast as ever, perovskites naturally became a hot topic in the solar cell research sphere.

But what makes metal halide perovskites unique? According to Olga Ovchinnikova, a co-author of the study, standard multicrystalline silicon-based solar cells have only ever reached a peak conversion efficiency of about 23% in the past 40 years. On the other hand, metal halide perovskites have already displayed higher conversion efficiencies in the past ten years alone.

As well as capturing light more efficiently, metal halide perovskites are more lightweight, flexible, and cost-efficient than silicon. As such, they can easily be manufactured into thin films that can be pasted onto virtually any surface.

Ovchinnikova also believes perovskites can go hand-in-hand with 3D printing to create a limitless number of functional solar-powered devices. She said, “We can use 3D printing to create wearables, put them on top of cars, and really democratize the use of perovskite solar cells. You could put them anywhere.”

Working towards longer-lasting perovskites

One of the main factors holding perovskites back is their poor durability when compared to silicon – they perform well but degrade and lose their efficiency over time. To make perovskites last longer, the ORNL team affirms that it’s important to understand the properties that enable their extraordinary performance in the first place.

To carry out such a pioneering and comprehensive study, the team had to develop a set of new methods to characterize everything from the chemical properties to the physical properties of the materials. Devices such as mass spectrometers and scanning probe microscopes weren’t enough, so the researchers looked to the capabilities of ORNL’s CNMS.

“A mass spectrometer doesn’t show us how the ions move,” explains Ovchinnikova. “So we used a novel instrument that combines a mass spectrometer and scanning probe microscope in one system. We also developed an approach on this system that enabled us to see the ions move while the material interacts with light in real time and incorporated new methods of machine learning to process the acquired data and simulate these behaviors.”

Having discovered that perovskite behaviors are actually determined by complex collections of properties acting together, the team has now filed patents for the methods they designed. Future work will involve using the techniques to develop more durable perovskites for solar cells, as well as using them on other classes of materials to understand their properties too.

“Now that we better understand some of the fundamental physics, we’re looking at how to engineer and improve the materials to enhance their photovoltaic effects,” Ovchinnikova said. “We can think about the next level.”

Further details of the study can be found in the paper titled ‘Ferroic Halide Perovskite Optoelectronics’.

Operating under the US Department of Energy, ORNL is home to all manner of technological advancements, including those related to additive manufacturing. Just recently, ORNL researchers announced the development of a novel water-soluble plastic binder that can be added to 3D printing materials and jetted into parts with “exceptional strength”. By tweaking a high-amine content, low molecular weight polyethyleneimine (PEI), the ORNL team has been able to tailor its properties in a way that doubles its strength compared to conventional binders.

ORNL also recently patented a novel cable-driven construction process that can be used to 3D print entire buildings via a suspension system. Named Sky Big Area Additive Manufacturing, or ‘SkyBAAM’ for short, the technology is designed to be operated using cords attached to cable winders, that provide users with full spatial control over the movements of the nozzle. The patent has since been disputed by two of the industry’s leading open-source 3D printing advocates – Drs. Adrian Bowyer and Joshua Pearce.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

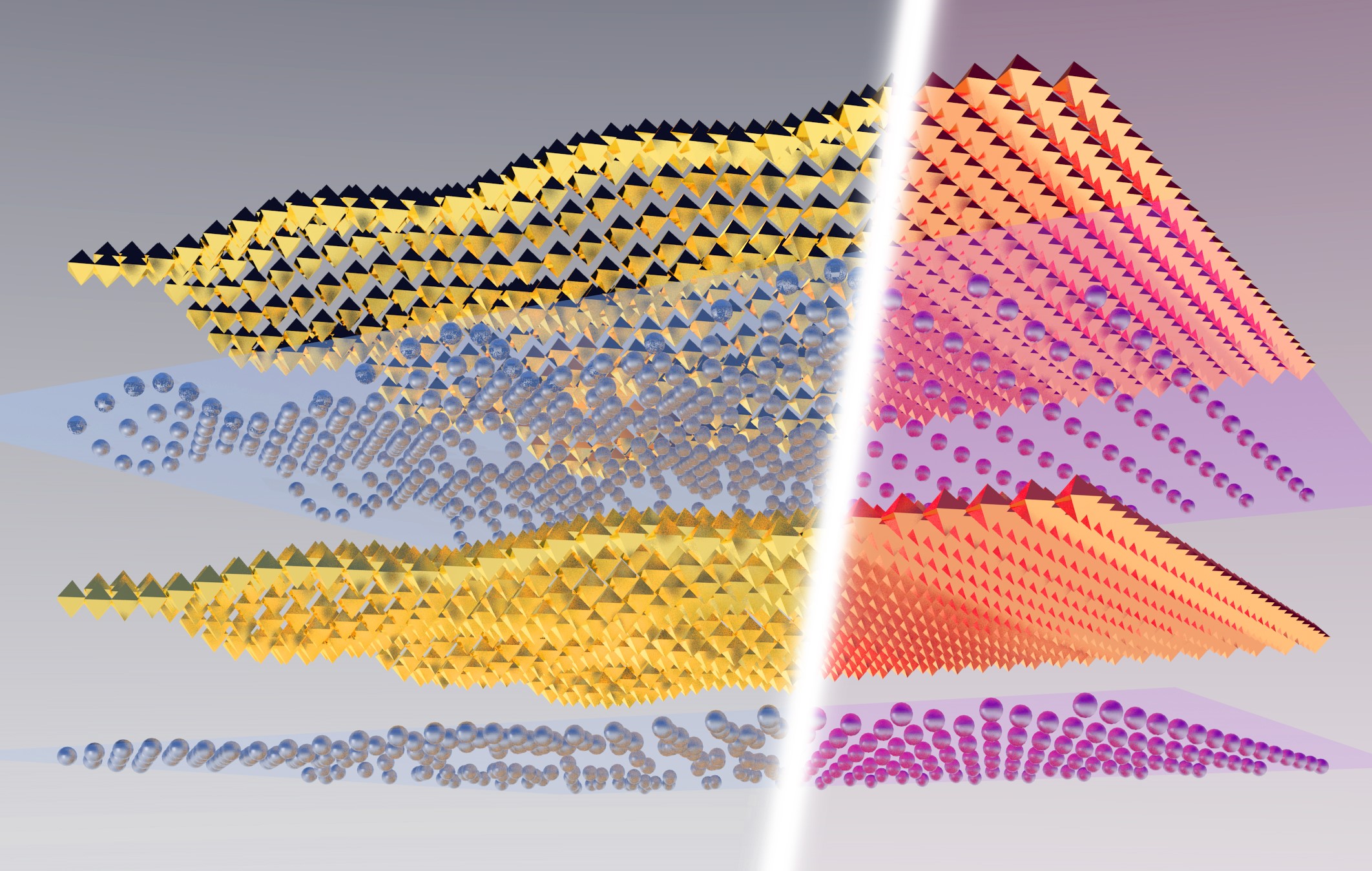

Featured image shows an illustration of lattice distortion, strain, and ion distribution in metal halide perovskites. Image via ORNL.

Kubi Sertoglu holds a degree in Mechanical Engineering, combining a love for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

© Copyright 2017 | All Rights Reserved | 3D Printing Industry

Author Profile

Latest entries

राशीफल2024.04.25Aaj Ka Rashifal: कर्क और कन्या राशि वालों को कार्यक्षेत्र में मिल सकती है तरक्की, पढ़ें दैनिक राशिफल – अमर उजाला

राशीफल2024.04.25Aaj Ka Rashifal: कर्क और कन्या राशि वालों को कार्यक्षेत्र में मिल सकती है तरक्की, पढ़ें दैनिक राशिफल – अमर उजाला लाइफस्टाइल2024.04.25Winter & Migraine: इस मौसम में ट्रिगर हो सकती है माइग्रेन की समस्या, जानिए इसके कारण और बचाव के उपाय – अमर उजाला

लाइफस्टाइल2024.04.25Winter & Migraine: इस मौसम में ट्रिगर हो सकती है माइग्रेन की समस्या, जानिए इसके कारण और बचाव के उपाय – अमर उजाला धर्म2024.04.25'राजनीति का धर्म ' या 'धर्म की राजनीति' | Relation Between Politics and Religion – Hindi Oneindia – Oneindia Hindi

धर्म2024.04.25'राजनीति का धर्म ' या 'धर्म की राजनीति' | Relation Between Politics and Religion – Hindi Oneindia – Oneindia Hindi टेक2024.04.2522 New Technology Trends for 2024: New Tech Horizons – Simplilearn

टेक2024.04.2522 New Technology Trends for 2024: New Tech Horizons – Simplilearn